Research & Development

- Home

- /

- Research & Development

Research and Development (R&D) at PSPL Group

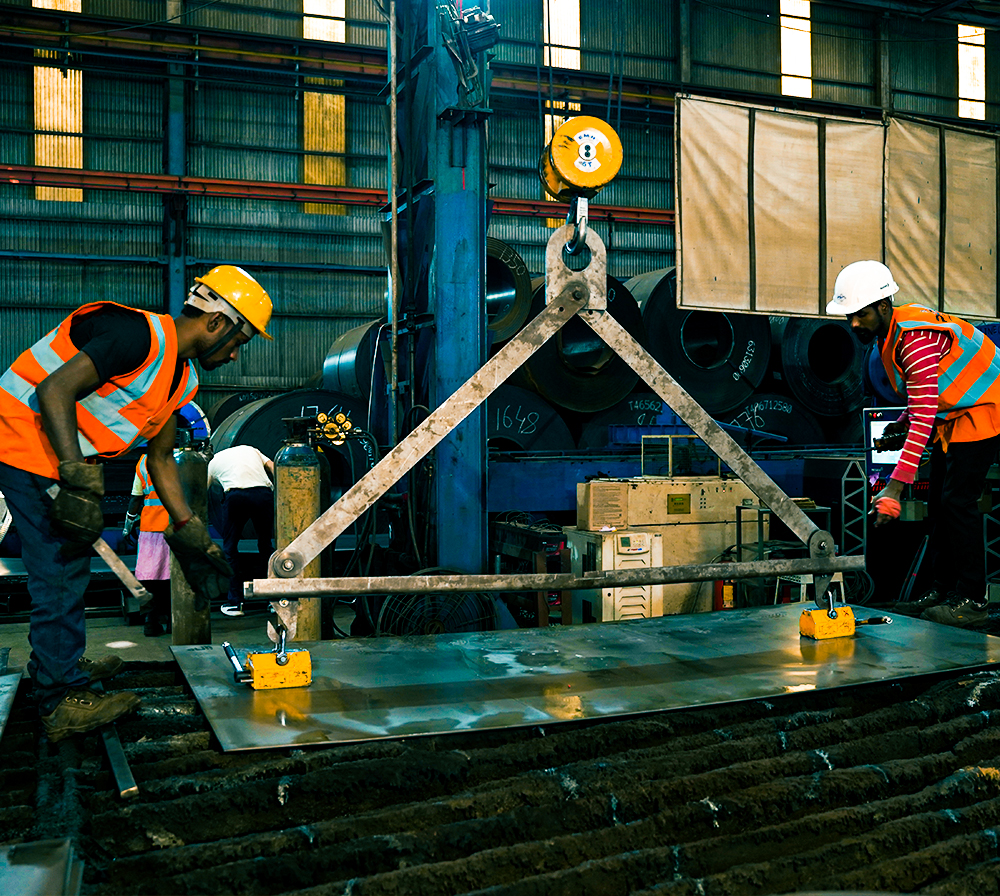

At PSPL Group, Research and Development (R&D) is the cornerstone of our commitment to innovation and excellence in the steel industry. Our R&D initiatives are focused on developing new technologies, enhancing product quality, and improving manufacturing processes to meet the ever-evolving demands of our customers and the market.

Key Areas of Focus:

- Material Science:

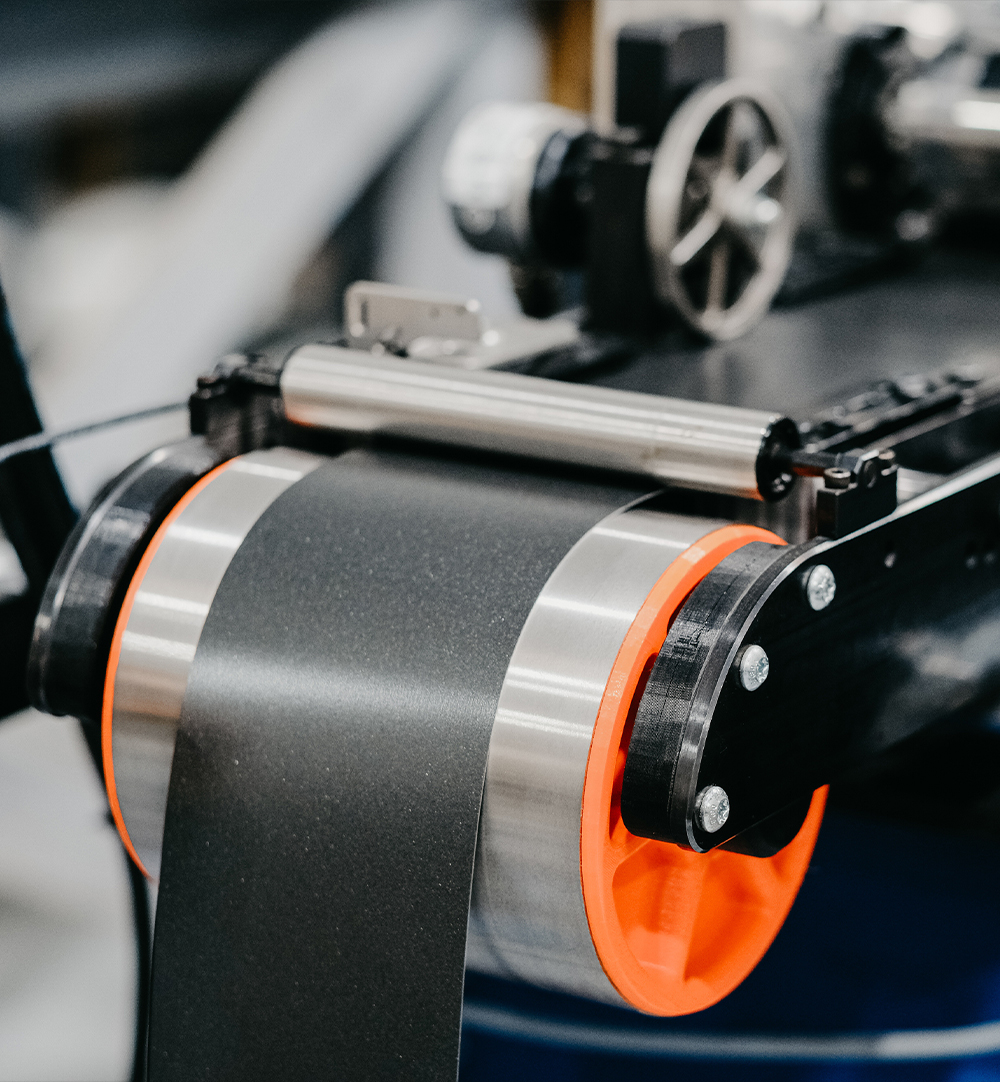

- Developing advanced steel grades with superior properties.

- Investigating new alloys and compositions for specific applications.

- Process Innovation:

- Optimising manufacturing processes to increase efficiency and reduce costs.

- Implementing advanced automation and robotics to enhance precision and productivity.

- Sustainability:

- Researching eco-friendly production methods and materials.

- Developing recycling technologies to minimise waste and reduce environmental impact.

- Product Development:

- Creating new steel products tailored to emerging market needs.

Enhancing existing products for better performance and durability.

Our Process

Cutting-Edge Innovation

Innovative Technologies

Innovative Technologies

- Advanced Manufacturing

- Sustainable Practices

- Product Enhancements

- Digital Transformation

R&D and Innovation Ecosystem

R&D and Innovation Ecosystem

- Innovation Hubs

- Collaborative Platforms

- Employee Empowerment

Achievements and Milestones

Achievements and Milestones

- Developed new steel grades that meet the stringent requirements of modern industries.

- Achieved significant reductions in energy consumption and emissions through innovative processes.

- Successfully launched several pioneering products that have set new industry benchmarks.